Forms

CaP Biomaterials manufactures the various calcium phosphate materials in a variety of physical forms. The sizes and shapes and other specifications for the forms are definable requirements.

Calcium phosphates are available sintered at various temperatures and conditions or unsintered for your own development purposes.

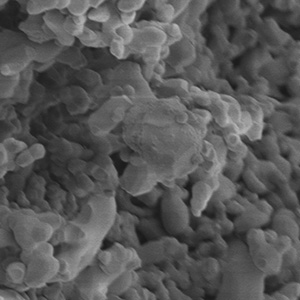

Press Feed

Molding and pressing operations as well as 3D printing need special powders customized for the fabrication technique. Such powders must meet a variety of performance criteria such as flow properties, compatibility with various slurring agents, chemical properties, and the ability to be sintered to consistent final shapes. With our knowledge of calcium phosphates, we can work closely with the customer to develop powders that are optimized for the customer’s processing equipment and procedures.

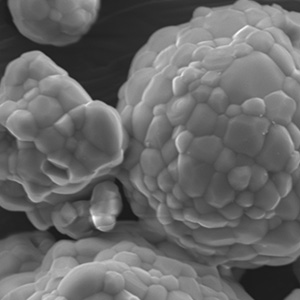

Spray Dried

Spray dried calcium phosphates are free flowing spherical powders with particle sizes generally between 25 and 100 microns. The main application is for plasma spray coating of a wide variety of orthopedic and dental implants. The spray dried powders are especially suited for this application because their free flow characteristics help the plasma spray equipment operate in consistent manner. CaP can customize these powders to meet the specific needs of the coating equipment and coating application(s).

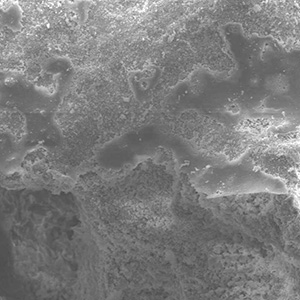

Porous Blocks

Porous blocks can be made in various shapes and sizes up to about 10 mm in the largest dimension. Porosity and pore size can be controlled within tight limits in a range of sizes, including mimicking cancellous bone. The composition can be pure β-TCP, pure HA, or any blend in-between. Strength can be varied by modifying the porosity. However, a limitation that applies to all blocks is that they cannot be used for load bearing applications.

Granulates

Granulates with wide variations in pore size, composition, particle size and dissolution characteristics can be provided for orthopedic and dental bone grafting. These can be produced as HA or TCP as well as biphasic HA/TCP and additional other calcium phosphates. Smaller sizes can be useful for periodontal and dental applications while larger particles are useful for orthopedic applications. Calcium phosphate granules can be made with pores sufficiently large for bone infiltration or can incorporate other size pores for other applications. Physical strength and controlled solubility can also be produced as required.

Dense granulate for soft tissue implants can be made in a variety of shapes and forms with controlled dissolution characteristics. These granules are usually made from hydroxyapatite and can be used in soft tissue augmentation or in various other boney implant sites.

Fine Powders

Powders are considered fine powders if the average particle size is below 10 microns. This also includes nano powders. Such powders are used to make a variety of products and, as such, are customized for each application both in terms of chemical composition and in physical properties. The nano powders can be supplied in a dried state as soft agglomerates with excellent hydration properties, or as stable slurries in organic solvents such as acetone or isopropanol.

Cements

Calcium phosphate cements set by growing new calcium phosphate crystals that form an interlocking structure. To achieve this, most calcium phosphate cements contain a metastable phase such as tetracalcium phosphate that can transform to a new (stable) crystal structure in body fluid at body temperature. Such transformations are often endothermic or mildly exothermic and so do not generate levels of heat that are damaging to surrounding cells and tissues. Cements can also be formed by an acid-base reaction, but these tend to generate potentially damaging levels of heat as they set. CaP can produce a metastable cement ingredient to be formulated into a cement by a customer, or a complete cement powder that is ready to package.

Carbonate Apatate Composite

This is a patented composite of calcium carbonate and hydroxyapatite. The matrix is hydroxyapatite and it contains micron sized crystals of calcium carbonate dispersed throughout. This results in a material that performs extremely well as a bone growth scaffold in animal models and has a resorption rate similar to tricalcium phosphate. It can be produced as a powder or a porous granulate and can be used as a substitute for HA or TCP in existing or new devices.

Putty

Putty formulations containing calcium phosphates are a popular finished product form since the putty matrix facilitates surgical placement and holds the calcium phosphate granules in place during irrigation and surgical closure. CaP supplies calcium phosphate granules for use in putties, but does not supply finished putty products. However, CaP can provide advice on putty formulations and even produce prototypes for evaluation. But the customer is ultimately responsibility for the putty design and manufacturing.